HISTORY OF FUJIGEN & FGN GUITARS

May 1960

Established in Nagano Prefecture, Japan through a joint capital investment, one million yen. In the guitar factory, first, only ten workers had manufactured trial products of violin and started to manufacture original classic guitars.

July 1960

Our classic guitars won the prize in Matsumoto woodwork festival held in Matsumoto city, Nagano.

May 1961

Chikuma factory opened and started to manufacture high-grade classic guitars. Then, we had a rush of orders and went into the black from this first year.

October 1962

Started to manufacture original electric guitars.

October 1963

Decided to guitar trade with USA in directly.

July 1966

Hirata factory opened to manage and control our productions and qualities well.

August 1967

Plywood factory opened.

October 1967

New York Sales Office opened.

January 1970

Increased the capital to 40 million yen.

May 1970

Stopped the direct trade and decided to focus on manufacturing our products as maker.

June 1972

Fujigen head office opened.

October 1972

Started a made-to-order system.

January 1973

Started to manufacture flat mandolins and banjos.

April 1974

Annual turn over 1.3billion yen a year.

April 1979

Started wood's direct imports.

January 1981

Introduced the world's first CNC ( Computer Numerical Control) router for manufacturing guitars.

November 1981

Started to manufacture original pickups.

April 1983

14 thousand-pieces of electric guitars were manufactured per month(this amount was the No.1 production all over the world.) Introduced high spec machine with a computer control.

October 1985

Share of guitar production: Overseas 80%, Domestic 20%

April 1989

Changed our corporate name to FUJIGEN Co., Ltd.

October 1989

Installed five division systems.(Guitar, Housing tools, Metals, New entry, Outdoor goods)

October 1990

Established Sunwood co., ltd. and released original guitar from FUJIGEN brand, "HEART-FIELD".

April 1997

Reorganization to two division systems as M.I(Music Instrument)division and C.A(Car Audio)division.

1999

Released original music boxes from FUJIGEN bland, "HEART-FIELD".

2001

Released original Japanese drums "Ryu-sho"(means Rising Dragon). Ikebukuro(Tokyo) FUJIGEN custom house No.1 opened.

May 2005

Shibuya(Tokyo) FUJIGEN custom house No.2 opened.

May 2006

Ikebukuro(Tokyo) FUJIGEN custom house No.1 removed in Tokyo.

July 2006

FUJIGEN's online shop opened.

October 2006

Exhibited our original guitars to PREMIUM GUITAR SHOW 2006, JAPAN.

November 2007

Exhibited FUJIGEN original guitar to Instrumental Fair 2007, JAPAN. Won the most valuable company prize in Japanese small and medium scale enterprises.

May 2008

Combined with Ikebukuro and Shibuya custom houses.

May 2008

Marketing dept. and Assembly process dept. of M.I division systems moved to Omachi factory, Nagano prefecture.

May 2009

Established FGN brand for overseas market.

The Greatest Guitar Manufacturing Company In Japan

Half a century of passion in wooden instruments

Established in 1960, FUJIGEN has been manufacturing guitars and basses for many world famous labels for half a century. As the original manufacturer, we sign responsible for the high quality (and probably for the success) of many of the worlds most respected brands.

Today, FUJIGEN is expanding into a global market with the aim to establish the name FUJIGEN as its original brand. FUJIGEN claims its leadership in the world of electric guitars due to its know-how in the treatment of wood.

Overseas and global Markets / Becoming No.1

At FUJIGEN we started with classical guitars manufacturing, but soon shifted to electric guitars to meet a quickly growing demand by overseas business partners, especially in the USA, where electric guitars were becoming very popular. Classical guitars remained our main product in the domestic Japanese market.

In the early 80's many famous brands had their production outsourced to so called OEMs (Original Equipment Manufactures).

FUJIGEN was a top OEM with great experience and production capacity. Our monthly output raised up to 14000 electric guitars. This was world leadership. In 1983, we had reached out goal.

Fujigen as OEM (Original Equipment Manufacturer)

In the 1970s FujiGen started making guitars (OEM) for companies such as Hoshino Gakki (Ibanez), CSL (Antoria), Kanda Shokai (Greco guitars) and Yamaha. In 1977/1978 FujiGen went into a joint venture with Roland to produce guitar synthesizers. In 1981 FujiGen opted out of acoustic guitar production to mainly concentrate on solid body guitar production. FujiGen obtained a CNC router in mid 1981 for making guitar parts and also began to manufacture their own pickups starting in late 1981.

In 1981/1982 FujiGen obtained the Fender Japan contract which lasted until 1996/1997. In mid/late 1992 FujiGen obtained a part of the Orville by Gibson contract which ended in 1998 and from then on have made Epiphone Japan solid body guitars, some Gretsch models and their own branded FgN guitars. FujiGen still does OEM guitar manufacturing for companies like Ibanez (Prestige Models) and Epiphone. FujiGen has three factories: the Omachi factory in Omachi, the Hirooka factory (established around 1992) in Shiojiri and the Matsumoto head office factory in Matsumoto.

Establishing FUJIGEN's original Brand (FGN Guitars)

As an OEM for top brands, we intend to tighten our position in terms of quality over quantity as a reliable partner. In order to attain a certain independence and to realize our own design ideas, we have launched our brand FGN for overseas market. We have opened two original custom houses in Ikebukuro and Daikanyama, Tokyo and we launched a Japanese online shop for FUJIGEN / FGN brand guitars and basses. We recently started establishing a worldwide distribution network for FGN branded products.

Our custom houses in Tokyo are the main sales point for FUJIGEN / FGN branded guitars and basses. The expert staff receives special orders for individually modified instruments and provides repair services. We care for quality customer service with thoroughness in dating and craftmanship. We are proud to do everything possible to satisfy our customers.

With all this, FGN is striving to use all of its assets as effectively as possible to make progress towards a top brand guitar maker with a big name: FGN Guitars

FGN FUJIGEN FACTORY TOUR

Oliver

Hartmann

Michael Sagmeister

Eamonn McCormack

Peter Geltat

Mirko Rum

Tommy Newton

.jpg)

Sham (Kaiser Franz Josef)

Oliver Hartmann

Michael Sagmeister

Eamonn McCormack

FGN FUJIGEN TECHNOLOGY

Low Setting Set Up /

Z Axis Deep Joint

and the others...

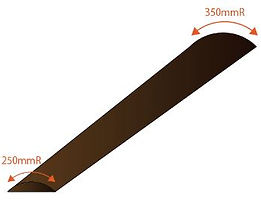

Compound Radius

FGN employs a specific "Compound Radius" ratio on the fingerboard, representing advanced fingerboard technology. The neck radius gradually increases over the finger board's length, starting out rounded near the headstock and flattening out toward the neck joint. A diameter of 250mm (10") was selected for the radius at the nut for optimal comfort and grip for chords. A 350mm (14") radius at the heel has proven to be ideal in eliminating any unwanted buzz of string bending that may be caused by over-tightened fingerboard radius traditionally countered by high string action. The Compound Radius affords comfortable and easy bends even with string action below 1.9mm and ensures smooth fingering when playing solo passages high on the neck.

Natural Satin Neck

Many people said the neck coated with gloss finish is very slippery and very difficult to hold it from sweating.

We finally developed FGN original natural satin finish and it can make you feel very smooth and comfortable like the illusion of touching the natural wood.

The original neck finish can improve your playability and the resonance from the neck to the body material.

Smooth Fret Edge

FGN craftsmen are meticulous in ensuring fret edges are rounded to perfection for a smooth feel on the neck. Position changes are seamless and the aesthetic is flawless.

2 Way Adjustable Bridge (JMJ)

2-Way adjuntable Bridge has two ways of string-guide holes, String-Through-Body style and Stop-Tail style.

While we'll apply the String-Through-Body style, we can feel super strong and tight sounds and amazing resonance even with the light gauge strings.

3&6 saddle-bridge (JIL)

We set up with vintage 3-saddle "Ash Tray" style bridge and 6-saddle bridge depending on all musician's intended use.

All bridge have adjustable saddle for string height, radius, and intonation.

Coil Tap Switch (JOS)

With the coil tap switch between the volume and tone control knob allows for split-coil tap on the bridge humbucker.